Distillation Column

Apps.DistillationColumn History

Show minor edits - Show changes to markup

(:html:)<font size=2><pre>

(:source lang=python:)

</pre></font> (:htmlend:)

(:sourceend:)

Multi-component Distillation Column

The distillation column in this example is built from a number of pre-existing model objects. The model objects used in this example include the distillation stage, feed, flash, mixer, splitter, stream lag, and vessel. These basic models are connected to form the multicomponent distillation tower.

- Distillation column model - 5 components, 8 stages

- (:html:)<a href="/online/view_pass.php?f=distill.apm">Solve Model Online Through a Web-based Interface</a>(:htmlend:)

(:htmlend:)

(:htmlend:)

Multi-component Distillation Column

The distillation column in this example is built from a number of pre-existing model objects. The model objects used in this example include the distillation stage, feed, flash, mixer, splitter, stream lag, and vessel. These basic models are connected to form the multicomponent distillation tower.

- Distillation column model - 5 components, 8 stages

- (:html:)<a href="/online/view_pass.php?f=distill.apm">Solve Model Online Through a Web-based Interface</a>(:htmlend:)

The figure below displays the system response after a step change in the reflux ratio from 3.0 to 1.5. Each trajectory represents the mole fraction of cyclohexane at each tray. The top reflux material becomes less pure (more n-heptane) due to the increased draw from the top of the column.

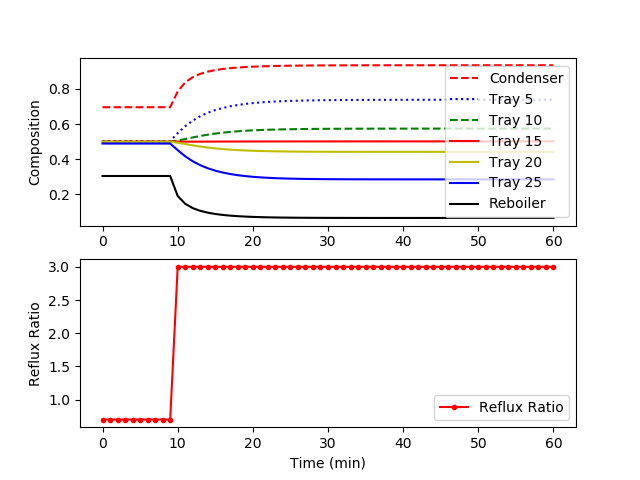

The model is available as a Python script with solution provided by GEKKO. The following figure shows a step change in the reflux ratio from 0.7 to 3.0.

(:source lang=python:) from gekko import GEKKO import numpy as np import matplotlib.pyplot as plt

- Initialize Model

m = GEKKO()

- Define constants

- Reflux Ratio

rr=m.Param(value=0.7)

- Feed flowrate (mol/min)

Feed=m.Const(value=2)

- Mole fraction of feed

x_Feed=m.Const(value=.5)

- Relative volatility = (yA/xA)/(yB/xB) = KA/KB = alpha(A,B)

vol=m.Const(value=1.6)

- Total molar holdup on each tray

atray=m.Const(value=.25)

- Total molar holdup in condenser

acond=m.Const(value=.5)

- Total molar holdup in reboiler

areb=m.Const(value=.1)

- mole fraction of component A

x=[] for i in range(32):

x.append(m.Var(.3))

- Define intermediates

- Distillate flowrate (mol/min)

D=m.Intermediate(.5*Feed)

- Liquid flowrate in rectification section (mol/min)

L=m.Intermediate(rr*D)

- Vapor Flowrate in column (mol/min)

V=m.Intermediate(L+D)

- Liquid flowrate in stripping section (mol/min)

FL=m.Intermediate(Feed+L)

- vapor mole fraction of Component A

- From the equilibrium assumption and mole balances

- 1) vol = (yA/xA) / (yB/xB)

- 2) xA + xB = 1

- 3) yA + yB = 1

y=[] for i in range(32):

y.append(m.Intermediate(x[i]*vol/(1+(vol-1)*x[i])))

- condenser

m.Equation(acond*x[0].dt()==V*(y[1]-x[0]))

- 15 column stages

n=1 for i in range(15):

m.Equation(atray * x[n].dt() ==L*(x[n-1]-x[n]) - V*(y[n]-y[n+1]))

n=n+1

- feed tray

m.Equation(atray * x[16].dt() == Feed*x_Feed + L*x[15] - FL*x[16] - V*(y[16]-y[17]))

- 14 column stages

n=17 for i in range(14):

m.Equation(atray * x[n].dt() == FL*(x[n-1]-x[n]) - V*(y[n]-y[n+1]))

n=n+1

- reboiler

m.Equation(areb * x[31].dt() == FL*x[30] - (Feed-D)*x[31] - V*y[31])

- steady state solution

m.solve() print(x) # with RR=0.7

- switch to dynamic simulation

m.options.imode=4 nt = 61 m.time=np.linspace(0,60,61)

- step change in reflux ratio

rr_step = np.ones(nt) * 0.7 rr_step[10:] = 3.0 rr.value=rr_step m.solve()

plt.subplot(2,1,1) plt.plot(m.time,x[0].value,'r--',label='Condenser') plt.plot(m.time,x[5].value,'b:',label='Tray 5') plt.plot(m.time,x[10].value,'g--',label='Tray 10') plt.plot(m.time,x[15].value,'r-',label='Tray 15') plt.plot(m.time,x[20].value,'y-',label='Tray 20') plt.plot(m.time,x[25].value,'b-',label='Tray 25') plt.plot(m.time,x[31].value,'k-',label='Reboiler') plt.ylabel('Composition') plt.legend(loc='best')

plt.subplot(2,1,2) plt.plot(m.time,rr.value,'r.-',label='Reflux Ratio') plt.ylabel('Reflux Ratio') plt.legend(loc='best')

plt.xlabel('Time (min)') plt.show() (:sourceend:)

The model is also available in the APMonitor Modeling Language. The figure below displays the system response after a step change in the reflux ratio from 3.0 to 1.5. Each trajectory represents the mole fraction of cyclohexane at each tray. The top reflux material becomes less pure (more n-heptane) due to the increased draw from the top of the column.

Distillation Columns

(:html:) <iframe width="560" height="315" src="https://www.youtube.com/embed/a6eIEeCrJdU" frameborder="0" allow="autoplay; encrypted-media" allowfullscreen></iframe> (:htmlend:)

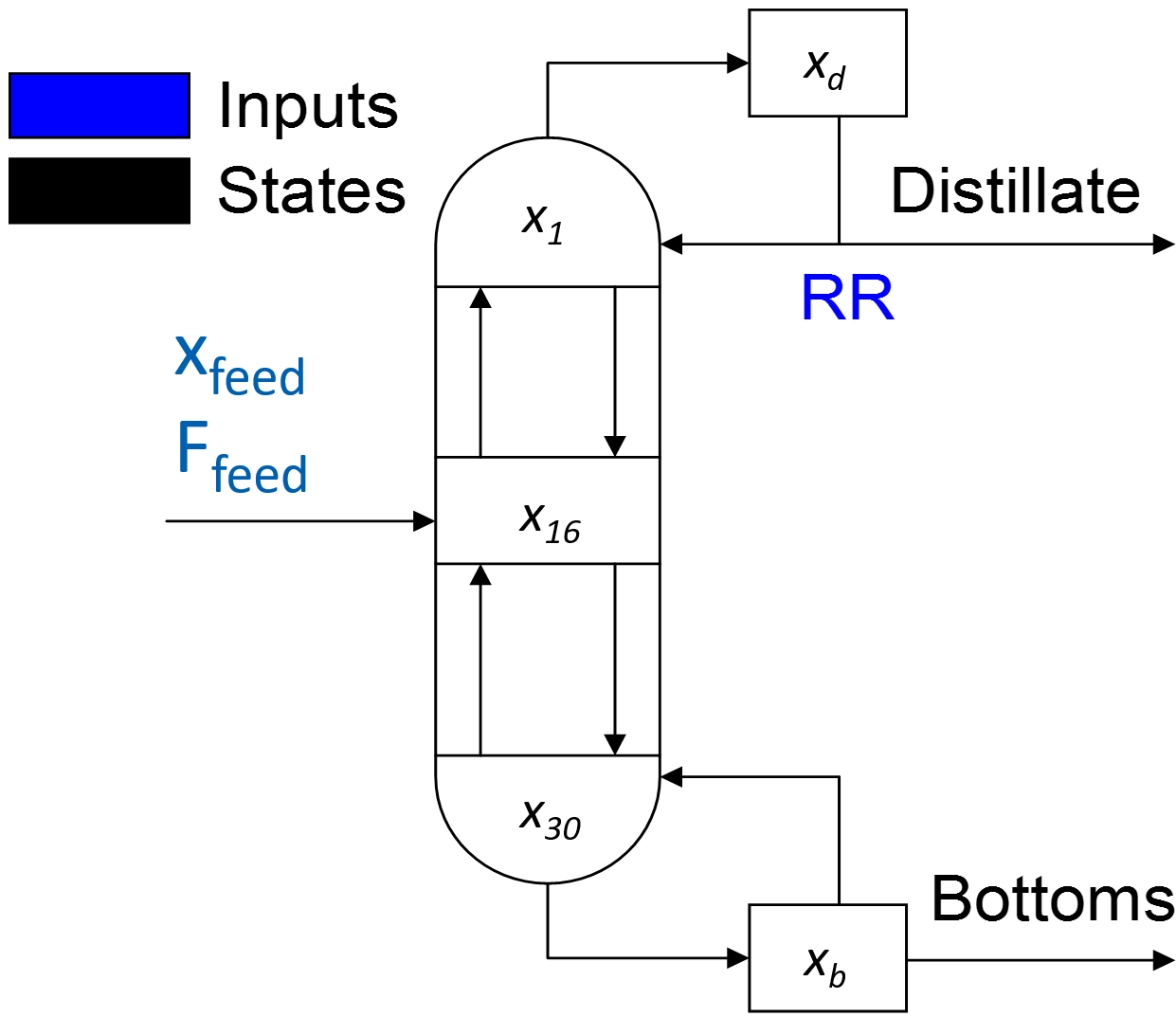

This distillation column is a separation of cyclohexane and n-heptane. The two components are separated over 30 theoretical trays. In general, distillation column models are generally good test cases for nonlinear model reduction and identification. The concentrations at each stage or tray are highly correlated. The dynamics of the distillation process can be described by a relatively few number of underlying dynamic states. This model was published in:

This distillation column is a separation of cyclohexane and n-heptane. The two components are separated over 30 theoretical trays. In general, distillation column models are generally good test cases for nonlinear model reduction and identification. The concentrations at each stage or tray are highly correlated. The dynamics of the distillation process can be described by a relatively few number of underlying dynamic states.

This model was published in:

- (:html:)<a href="/online/view_pass.php?f=distill.apm">Solve Model Online Through a Web-based Interface</a>(:htmlend:)

(:html:)<font size=1><pre>

(:html:)<font size=2><pre>

Hahn, J. and T.F. Edgar, An improved method for nonlinear model reduction using balancing of

empirical gramians, Computers and Chemical Engineering, 26, pp. 1379-1397, (2002)

Hahn, J. and T.F. Edgar, An improved method for

nonlinear model reduction using balancing of

empirical gramians, Computers and Chemical

Engineering, 26, pp. 1379-1397, (2002)

- [https://apmonitor.ath.cx/online/view_pass.php?f=distill.apm| Solve model online]

- Solve model online

- [https://apmonitor.ath.cx/online/view_pass.php?f=distill.apm| Solve model online]

APMonitor Modeling Language

https://www.apmonitor.com

Binary Distillation Column from

Hahn, J. and T.F. Edgar, An improved method for nonlinear model reduction using balancing of

empirical gramians, Computers and Chemical Engineering, 26, pp. 1379-1397, (2002)

Liquid mole fraction of component A

at reflux ratio = 2

Condenser 0.93541941614016

Tray 1 0.90052553715795

Tray 2 0.86229645132283

. 0.82169940277993

. 0.77999079584355

. 0.73857168629759

. 0.69880490932694

. 0.66184253445732

. 0.62850777645505

. 0.59925269993058

. 0.57418567956453

. 0.55314422743545

. 0.53578454439850

. 0.52166550959767

. 0.51031495114413

. 0.50127509227528

. 0.49412891686784

. 0.48544992019184

. 0.47420248108803

. 0.45980349896163

. 0.44164297270225

. 0.41919109776836

. 0.39205549194059

. 0.36024592617390

. 0.32407993023343

. 0.28467681591738

. 0.24320921343484

. 0.20181568276528

. 0.16177269003094

Tray 29 0.12514970961746

Tray 30 0.09245832612765

Reboiler 0.06458317697321

Model binary

Parameters

! reflux ratio

rr = 0.7

! Feed Flowrate (mol/min)

Feed = 2.0 ! 24.0/60.0

! Mole Fraction of Feed

x_Feed = 0.5

! Relative Volatility = (yA/xA)/(yB/xB) = KA/KB = alpha(A,B)

vol=1.6

! Total Molar Holdup in the Condenser

atray=0.25

! Total Molar Holdup on each Tray

acond=0.5

! Total Molar Holdup in the Reboiler

areb=0.1

End Parameters

Variables

! mole fraction of component A

x[1:32] = 0.3

End Variables

Intermediates

! Distillate Flowrate (mol/min)

D=0.5*Feed

! Flowrate of the Liquid in the Rectification Section (mol/min)

L=rr*D

! Vapor Flowrate in the Column (mol/min)

V=L+D

! Flowrate of the Liquid in the Stripping Section (mol/min)

FL=Feed+L

! Vapor Mole Fractions of Component A

! From the equilibrium assumption and mole balances

! 1) vol = (yA/xA) / (yB/xB)

! 2) xA + xB = 1

! 3) yA + yB = 1

y[1:32] = x[1:32]*vol/(1+(vol-1)*x[1:32])

End Intermediates

Equations

! condenser

acond * $x[1] = V*(y[2]-x[1])

! 15 column stages

atray * $x[2:16] = L*(x[1:15]-x[2:16]) - V*(y[2:16]-y[3:17])

! feed tray

atray * $x[17] = Feed*x_Feed + L*x[16] - FL*x[17] - V*(y[17]-y[18])

! 14 column stages

atray * $x[18:31] = FL*(x[17:30]-x[18:31]) - V*(y[18:31]-y[19:32])

! reboiler

areb * $x[32] = FL*x[31] - (Feed-D)*x[32] - V*y[32]

End Equations

End Model

(:html:)<font size=1><pre>

</pre></font> (:htmlend:)

This distillation column is a separation of cyclohexane and n-heptane. The two components are separated over 30 theoretical trays. In general, distillation column models are generally good test cases for nonlinear model reduction and identification. The concentrations at each stage or tray are highly correlated. The dynamics of the distillation process can be described by a relatively few number of underlying dynamic states. This model was published in

This distillation column is a separation of cyclohexane and n-heptane. The two components are separated over 30 theoretical trays. In general, distillation column models are generally good test cases for nonlinear model reduction and identification. The concentrations at each stage or tray are highly correlated. The dynamics of the distillation process can be described by a relatively few number of underlying dynamic states. This model was published in:

Multi-component Distillation Column

Binary Distillation Column with 30 trays (cyclohexane n-heptane)

Distillation column models are generally good test cases for nonlinear model reduction and identification. The concentrations at each stage or tray are highly correlated. The dynamics of the distillation process can be described by a relatively few number of underlying dynamic states. A couple papers have been published with this model as an example application. One in particular is:

Binary Distillation Column

This distillation column is a separation of cyclohexane and n-heptane. The two components are separated over 30 theoretical trays. In general, distillation column models are generally good test cases for nonlinear model reduction and identification. The concentrations at each stage or tray are highly correlated. The dynamics of the distillation process can be described by a relatively few number of underlying dynamic states. This model was published in

The distillation column in this example is built from a number of pre-existing model objects. The model objects used in this example include the distillation stage, feed, flash, mixer, splitter, stream lag, and vessel. These basic models are connected to form the multicomponent distillation tower.

Binary Distillation Column with 30 trays (cyclohexane n-heptane)

Distillation column models are generally good test cases for nonlinear model reduction and identification. The concentrations at each stage or tray are highly correlated. The dynamics of the distillation process can be described by a relatively few number of underlying dynamic states. A couple papers have been published with this model as an example application. One in particular is:

Hahn, J. and T.F. Edgar, An improved method for nonlinear model reduction using balancing of empirical gramians, Computers and Chemical Engineering, 26, pp. 1379-1397, (2002)

The figure below displays the system response after a step change in the reflux ratio from 3.0 to 1.5. Each trajectory represents the mole fraction of cyclohexane at each tray. The top reflux material becomes less pure (more n-heptane) due to the increased draw from the top of the column.